0

Incoming matrixes ton/a

0

Biomethane injected in the grid Smc/a

Innovative technology and know how come together in the production process, Superdry Italian Management System, developed by the start-up Waste to Methane, to improve the plant performance and the energy consumption, staying true to the very company mission.

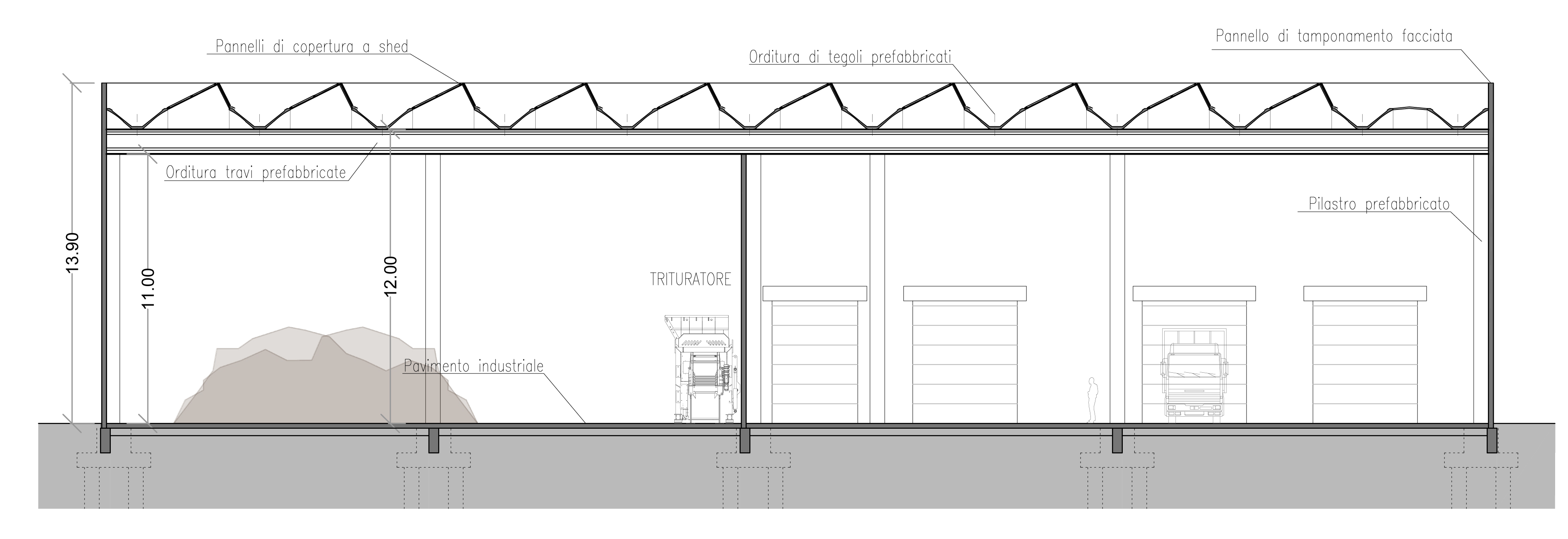

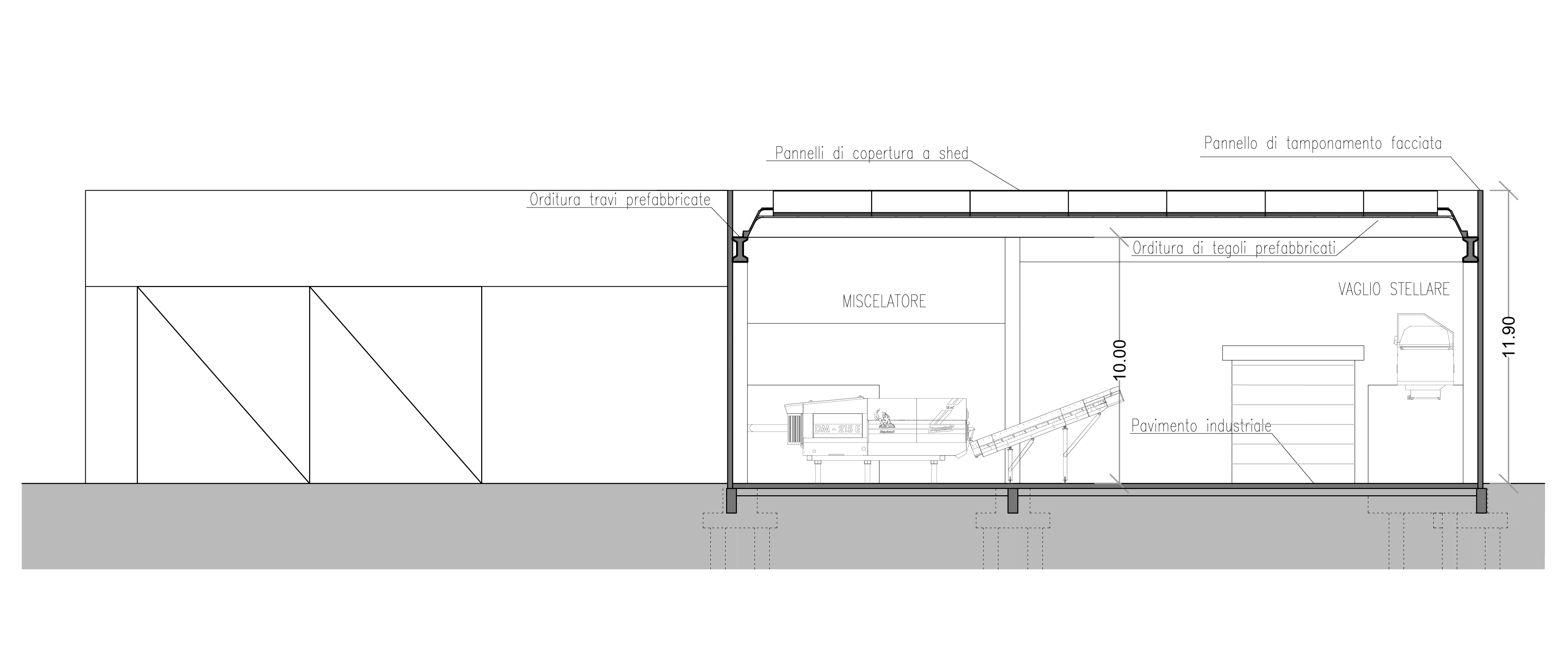

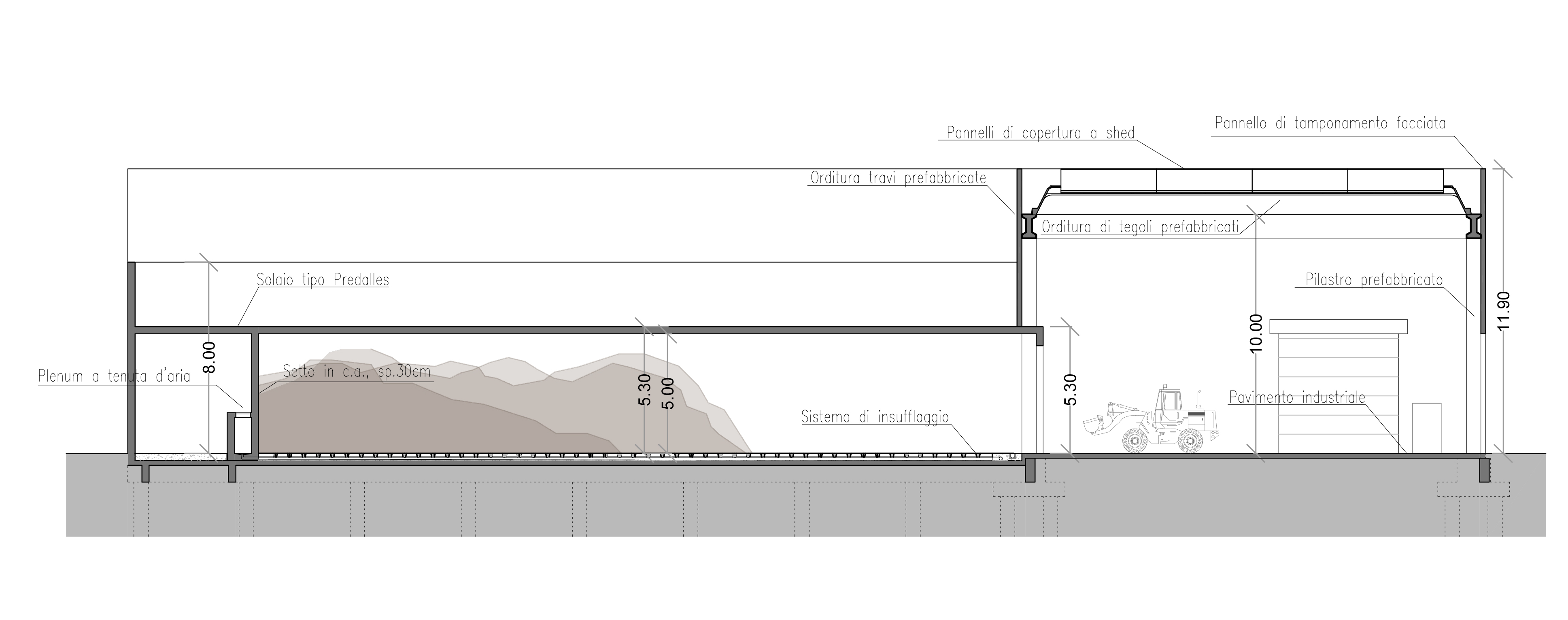

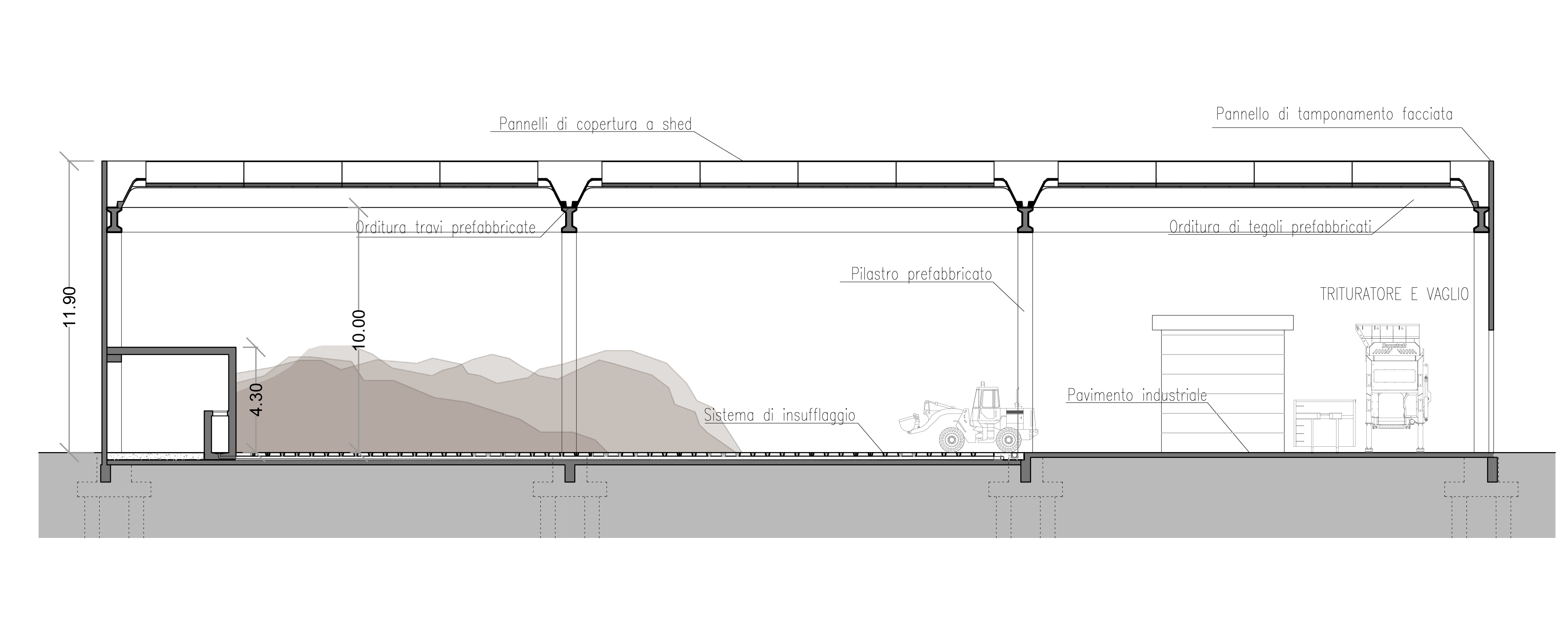

Waste to Methane is been tendered the executive planning, building and upgrading of the existing Composting plant, part of the recovery platform located in “Macchiareddu”, in the borough of Capoterra of the great metropolitan city of Cagliari, presently fully operational in aerobic mode.

The client which has handled the project is the Consorzio Industriale Provinciale di Cagliari, which has the objective of recovering the organic fraction of the munocipal waste, with production of soil amender , and, through the anaerobic section, and successive co-generation, producing energy and ensuring at the same time minimum environmental impact, in terms of athmosferic emissions.

The operation, entirely financed by the dalla Regione Autonoma Sardegna involves the updating and upgrading of the existing composting plant, the construction of an anaerobic digestion plant, based on “Dry” technology, fully fitted of pre-treatment and biogas upgrading, capable of treating 50.000 tons per annum of organic waste from the urban collection, to turn into 4.250.000 smc of biomethane.

Waste to Methane

High-tech energy,

waste turns into biomethane